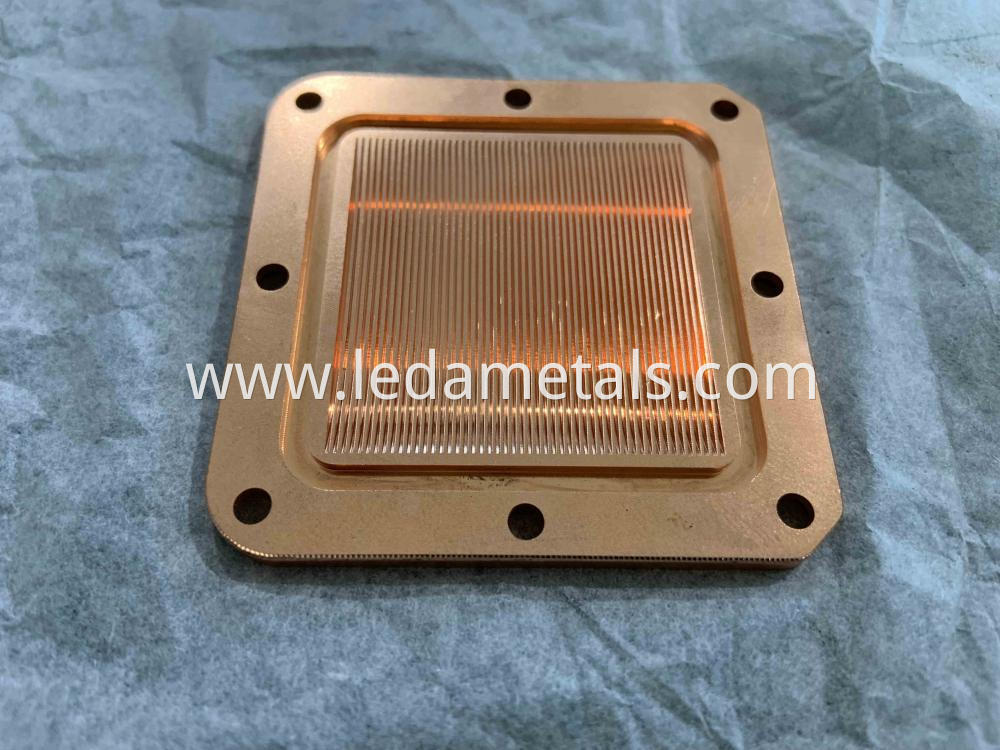

Custom High Density Skiving Copper Fin CNC Radiator

$100≥1Piece/Pieces

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,CIF,EXW,FOB,FCA,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Xiamen |

$100≥1Piece/Pieces

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,CIF,EXW,FOB,FCA,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Xiamen |

Model No.: LD034

Brand: LD

Types Of: Drilling, Laser Machining, Milling, Turning

Machinable Materials: Aluminum, Copper

Whether Micro Processing: Micro Machining

Place Of Origin: China

Whether CNC Machining: Cnc Machining

| Selling Units | : | Piece/Pieces |

| Package Type | : | Custom |

1. Features:

Blades are scooped out one by one from a sheet of aluminum or copper using a special knife (spatula) and set upright

2. Advantage:

The high density radiator can be made by breaking through the limit of thickness to length ratio of conventional heat sink

Blade and base are integrated, there is no interface impedance problem, the heat dissipation effect is very good, close to Aluminum Extrusion radiator, widely used in photovoltaic industry, electric vehicles, inverters, communication products and so on

3. Weakness

The processing cost is high, and the waste generated, has a certain defect rate, the product cost is relatively high, when the shovel is very long radiator, every 150mm length will have a 4mm or so section ditch

4. The maximum tooth width is 800mm, the tooth height is 100mm, and the pitch is 0.1mm ~7.5mm

Thickness of 0.1 mm to 7.5 mm

Tolerance of + / - 0.2 mm

1. NDA will be signed according to your request;

2. Make the cost evaluation in 1 day once we receive your drawings;

3. Provide a prototyping for your confirmation before manufacturing;

4. As the increasingly deversified needs make orders multiple and small-batched,our low-volumn manufacturing services help to support your product development;

5. Rooted in metal processing for 10 years, our engineers and overseas sales team accumulated much experience in this field, they have no obstacles in talking with customers, can rapidly get customer's idea;

6. With their good knowledge, along with the technologies like CNC machine, sheet metal, skiving, stamping, bending and a range of finishing services, your project idea will come out precisely according to your expectation;

7. In same quality, we uasually be more competitive than others in price;

8. No tolerance in quality and delivery.

Materials

Stainless steel, copper, brass, carbon steel, aluminum, etc.

According to customer's requirement.

Surface Treatment

Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, black anodized, sliver anodized, different color powder coating, rust preventive oil and etc.

Products Scope

water-cooling plate, radiator, heatsinks, automobile parts, aerospace parts, electric case, enclosures, housing, machinery engine part, precision accesories, gears, switch, knob, hardwares, plastic molding injection parts, etc.

Producing Equipment

CNC machine , automatic lathe machine, stamping machine, CNC milling machine, rolling machine, lasering, tag grinding machine, die casting machine, extrusion machine, and etc.

Management System

ISO9001 - 2008

Certificates

RoHS, SGS, Raw Material Certification

Testing Equipment

Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector, etc.

Lead time

20-30 working days as usual, based on the detailed order quantity.

Warranty

Replacement at all our cost if there is our fault.

About Returned Goods

Quality problem or deviation from drawings

How to order

* You send us drawing or sample.

* Engineers perform a design analysis, evaluate the feasibility in production and optimize the solution if it is necessary;

* Rapid-prototyping for your confirmation before manufacturing;

* Start production and deliver your custom parts to your location with no delay.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.