Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1. Extruded aluminum radiator type, or skiving radiator type (see Figure 1): fin and substrate is one. There is no splicing, the internal heat conduction of the radiator is uniform, high thermal conductivity. Disadvantages are limited by processing technology, radiator size and fin spacing, thickness, piece height are limited.

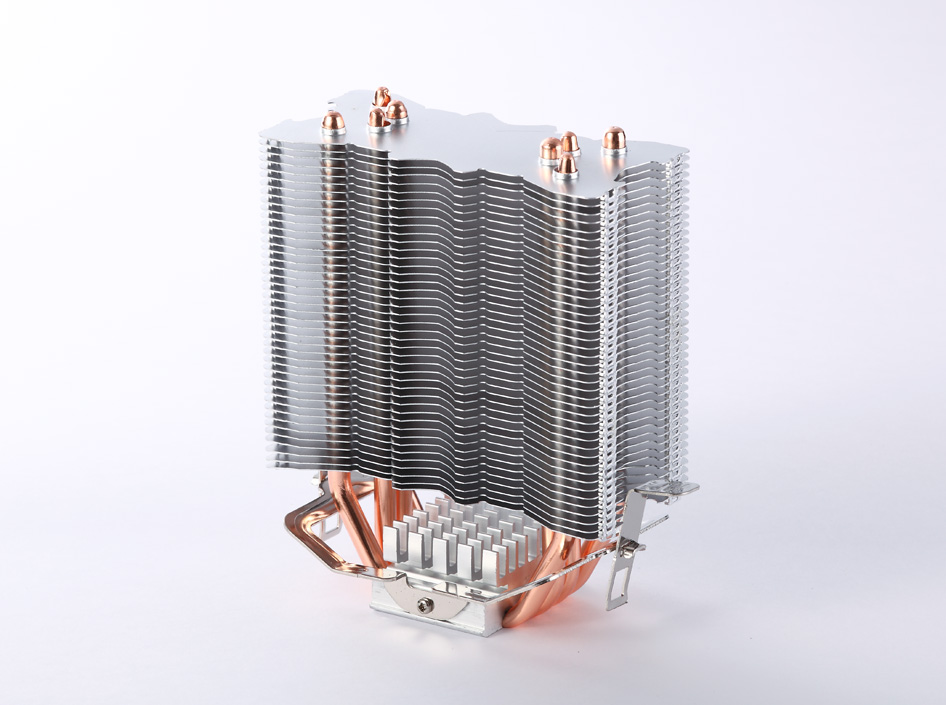

2. Fin splicing type (superplate radiator) (see Figure 2): make fins first, and then stack the fin root together, after pressure processing, tightly occluded between the pieces into one. This process can be made into any width, high fin radiator. The problem is that the sheets are separated and the thermal resistance is large. The thermal conductivity is greatly reduced.

3. Insert fin radiator (see Figure 3): it is composed of a bottom plate and several fins. One side of the bottom plate is first planted with iron inserts, and one end of the superplate is inserted into the insert slot and pressed tightly. This kind of radiator has only a small part of the end of the aluminum sheet inserted into the bottom plate, the contact thermal conductivity area is limited, the thermal resistance will be large. The consistency of thermal resistance parameters is also poor.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.